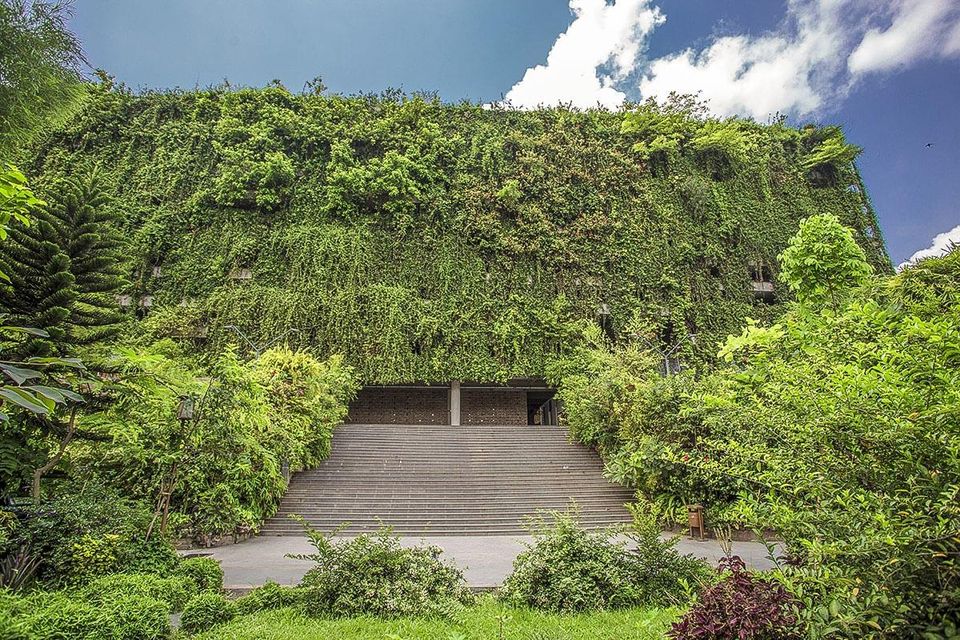

Lush vines and creepers scrawling down the facade gives the first impression that the building, engulfed by greeneries, can breathe by itself. As you move closer to the building and step up the grand plaza, the building sheds off its sublimity and welcomes you along a corridor with water pockets on either side and walls featuring earthen dolls, mud bowls, clay lamps etc. at intervals, and gradually a splashing sound grows louder & clearer, and you will be awestruck by the water oozing out of the earthen pots drizzling down from a height to make this sound like music to the ears. Thus, the Karupannaya Factory, an architectural marvel not only in terms of aesthetics and sensory experience but also in consideration of sustainability, grabs anyone’s attention immediately, and when I came to learn about its LEED platinum certification, none could stop me from making a visit to Rangpur even during the pandemic. Gradually, I came to learn how the building in fact provides for itself, consuming as little natural resources as possible.

The sublime scale of the building can only be realized in physical presence, not from pictures. 4 atriums each of around 34’ diameter, flood in sunlight into this massive building of 136’ by 380’, keeping the internal spaces bright & cheery. The sunlight also keeps away moulds from growing in the water, and breeze from the south keeps the water flowing most of the time. The north of the building facade has been so designed to let in adequate diffused sunlight in the internal spaces. Thus, sunlight, one of the most important easily available natural resource, has been efficiently put to use in the building design.

The breeze flowing from the south first blows over the greeneries cooling down a bit and then pass over the water further cooling down, and ultimately spreads across the internal spaces. Thus, the breeze cools down so much so that the workers are working comfortably even without the use of ceiling fans or air conditioners. Moreover, functions like dining, storage & training that are not regularly and continually used are placed on the west, and the 21’ wide ramp is placed on the east so that these spaces act as buffer for heat transmission, and the workers can work as comfortable as possible. In fact, the temperature inside the factory building is at least 7 degrees Celsius cooler than that of outside during summer whereas during winter the temperature difference is around 5 degrees Celsius. The building is, thus, passively ventilated, which is a trend in sustainability growing popularity day by day.

Maintenance of the greeneries is a major concern of the gardeners whose job has been made easier by suggesting drip irrigation as a means of watering the plants without depleting such valuable natural resource like water, which is usually the case when regular irrigation techniques are used. The water pockets, which hold processed water of 220 cubic meters, coming from the ETPs, act as emergency reservoirs in case of fire events and can also be recycled to be reused in the dyeing section of the factory. Some of these water pockets were also designed to harvest rainwater of volume 975 cubic meter; hence reducing dependency on groundwater, which is 1,84,567 cubic meter in volume annually. Thus, the building maintains a closed-loop water cycle for its variety of operations.

The zero discharge ETP needed for recycling water is a state-of-the-art design by technology expert, Panta Rei. The display runs around the clock, presenting sets of data and diagrams on the processes running in the plant, and the machine automatically adjusts the mechanism for pH balance when the data indicates any imbalance in pH level in the effluent. And when the effluent is safe to be distributed in the water reservoirs, the machine automatically turns off, and the ETP sludge is sold to Lafarge Surma cement factory.

The factory’s electricity consumption is supplemented by renewable energy. A solar power plant generating 89 KW has been set up on the rooftop can provide for only 1% of total electricity consumption of total 2,546,000 KW in the factory. An exceptional feature of this green building is the use of rice husk boilers; two boilers of 5 tons & 3 tons capacity use rice husk coming from the neighborhood as fuel to generate heat that is used to operate dryers in the dyeing section. The ash generated by the boiler is safely disposed of.

The building was made more sustainable by adding Biogas plant, occupying small underground area, located between ETP & boiler room, which generates fuel from food waste. This gas fuel is used in burner for cooking as well as in composting fertilizer for the landscaped greeneries. Also, the factory staffs are trained to collect wastes every day and categorize these into biodegradable or non biodegradable substances. The biodegradable ones like food and tree clippings are collected every day to be used in the biogas plant whereas the non biodegradables are separated for reuse or recycling. Thus, the factory maintains a strong waste management policy.

The twenty-one feet wide ramp granting vehicular access to all the floors makes vertical transport of heavy cartons quite convenient that too without energy consumption as is required in vertical transportation through service lifts. For green cleaning, vacuum cleaner of brand, Taski Vento, was used, which helped score a point in LEED. Moreover, diverse use of categories like discount shop, child care facility and full-time doctor within the factory campus helped the building score another point in sustainability. Thus, one credit added up with another leading to the LEED Platinum certification for the building in the Operations & Maintenance category, inspiring many other projects to look up to green building certifications in the days to come.